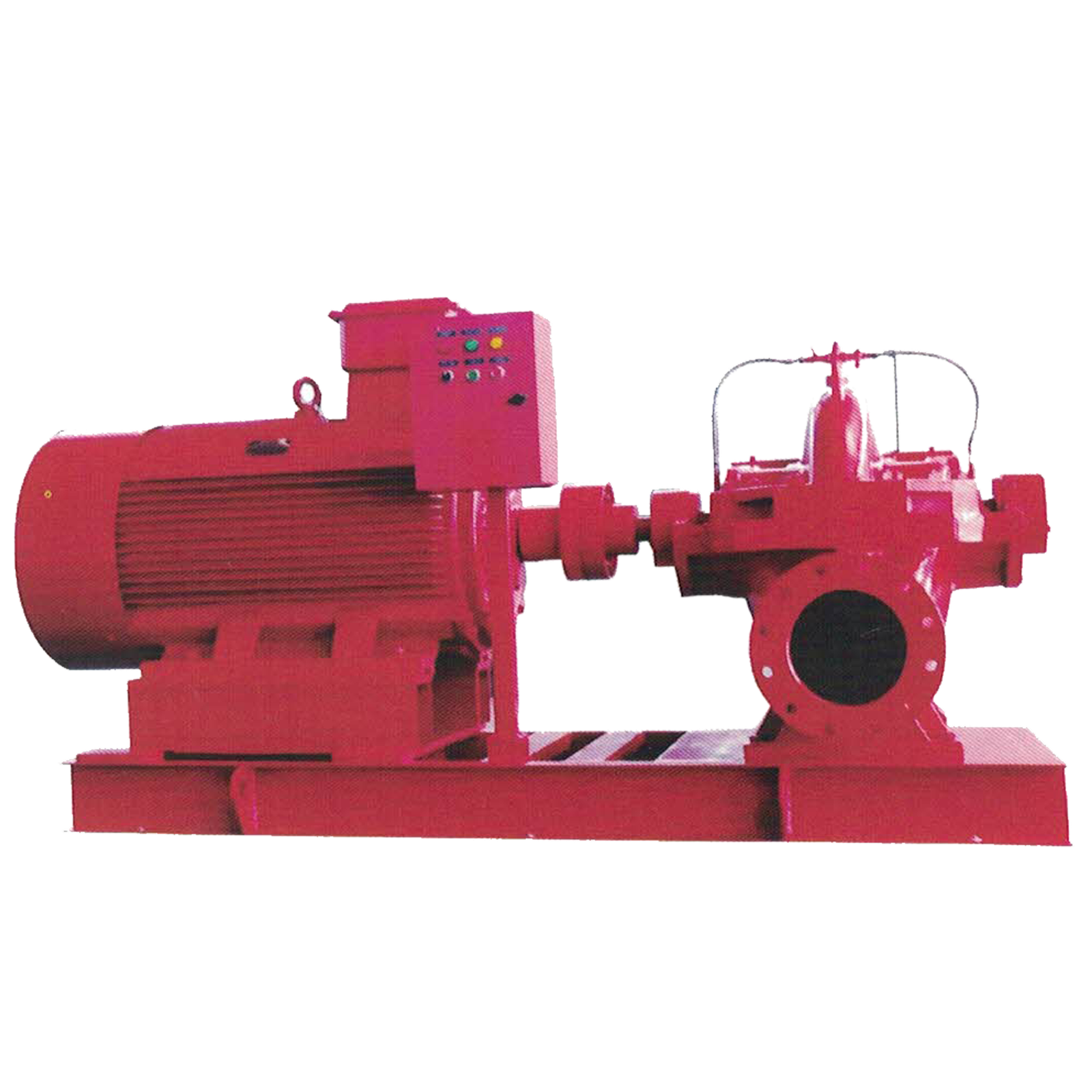

Horizontal multi-stage fire pumps are mainly used for pressurized water delivery in fire protection systems, and can also be used for mine water supply and drainage. The flow range of the delivered liquid is 5-8L/S, the pressure range is 0.2-2.25MPa, the matching power range is 1.5-200KW, and the caliber range is ¢50-¢250mm. The single-suction single-stage fire pump consists of two parts: the motor and the pump. The fire pump and the motor are coaxial, and the pump structure includes the pump body, impeller, pump cover, mechanical seal, etc. The pump inlet and outlet are on the same horizontal axis, and the caliber specifications are the same, which is very convenient for loading and unloading and occupies a small area. The pump is equipped with a mounting base for easy installation and increased stability of the pump operation. The pump seal adopts a mechanical seal, which has the characteristics of reliable sealing and no leakage. The axial force of the pump is balanced by a balancing ring on the impeller. The inlet and outlet flanges of the pump are designed according to the 1.6MPa pressure, and the pipeline is convenient to match. The single-suction multi-stage segmented fire pump consists of two parts: the motor and the pump. The motor is a Y-type three-phase asynchronous motor. The fire pump and the motor are connected by a coupling. The whole is rigidly connected and does not need to be corrected during use. The fire pump consists of a stator part and a rotor part. The stator part of the fire pump consists of parts such as the water inlet section, the middle section, the guide vane, the water outlet section, and the stuffing box body. To prevent stator wear, the stator is equipped with sealing rings, balance sleeves, etc., which can be replaced with spare parts after wear. The rotor part consists of a shaft, a middle wheel, a balance drum, etc. The lower end of the rotor is a water-lubricated bearing, and the upper part is an angular contact ball bearing. Most of the axial force of the pump is borne by the balance drum, and the remaining small part of the residual axial downward force is borne by the angular contact ball bearing. The combined paper pads of the water inlet section, the middle section, and the water outlet section are tightened to achieve sealing, and users can choose according to their needs.

Product features of horizontal multi-stage fire pump

1. The fire pump has a compact structure, small size and beautiful appearance. Its vertical structure determines that the installation area is small, and its center of gravity is at the center of the pump foot, which enhances the running stability and service life of the pump.

2. The suction and discharge ports of the fire pump are both horizontal, which simplifies the connection of the pipeline.

3. The multi-stage type can be installed in the same direction or in several different directions of 90°180°270° to meet different connection occasions according to needs.

4. The pressure of the fire pump can be increased or decreased according to the needs of the water pump stage and the outer diameter of the impeller can be cut to meet it without changing the installation area, which is not available in other pumps.

5. The fire pump rotor has a small winding, stable operation, low vibration, low noise and long service life.

Product use of horizontal multi-stage fire pump

XBD-W fire pump is mainly used for pipeline pressurization and water delivery in fire protection systems. It can also be used in industrial and urban water supply and drainage, high-rise building pressurized water supply, long-distance water supply, heating, bathroom, boiler hot and cold water circulation pressurized air conditioning refrigeration system water supply and equipment matching, replacing the original IS type.

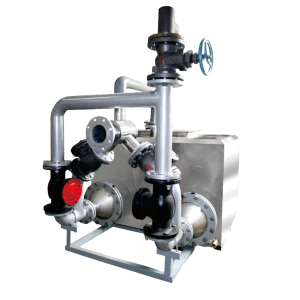

XBD-JSS series split case double suction fire pump set

1. Compact structure, small footprint

2. Convenient connection, beautiful appearance

3. Flexible installation, strong applicability

4. Flexible performance adjustment

5. Smooth operation, low noise

6. Reliable sealing, no leakage

7. Axial force balance design

8. Reasonable design of inlet and outlet flanges

9. Wide range of applications

longqi168

You must be logged in to post a review.

Reviews

There are no reviews yet.